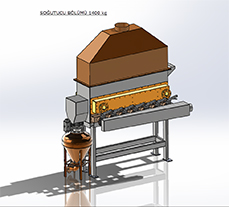

SILICA SAND RECOVERY - Thermal Sand Regeneration Machine (Golden Sand 1 / 2 / 3 ton / hour capacity)

Golden Sand allows you to reuse casted silica sand up to a certain number of times, reducing your sand costs, which is the main cost parameter of the casting mold. In addition, for operators, observing the environmental directives of foundry waste, which is a large amount of sand, provides economic contribution by reducing the workload and risk of compulsory storage and disposal procedures.

Golden Sand System

By using air tuyere and fluidized-bed technology the casted silica have been burned at different temperatures at different combustion chambers gradually. All the bounded resin shells are fully burnt and hot reclaimed sand is obtained at the outlet of the combustor. After having sand is cooled at 28-30°C in cooler unit, it is delivered by pneumatic transporter to new sand storage silo. Finally, grain size distribution in thermal reclaimed silica is ideally distributed and efficiently obtained without sand degradation fail.